Ways to reduce the cost of compressed air

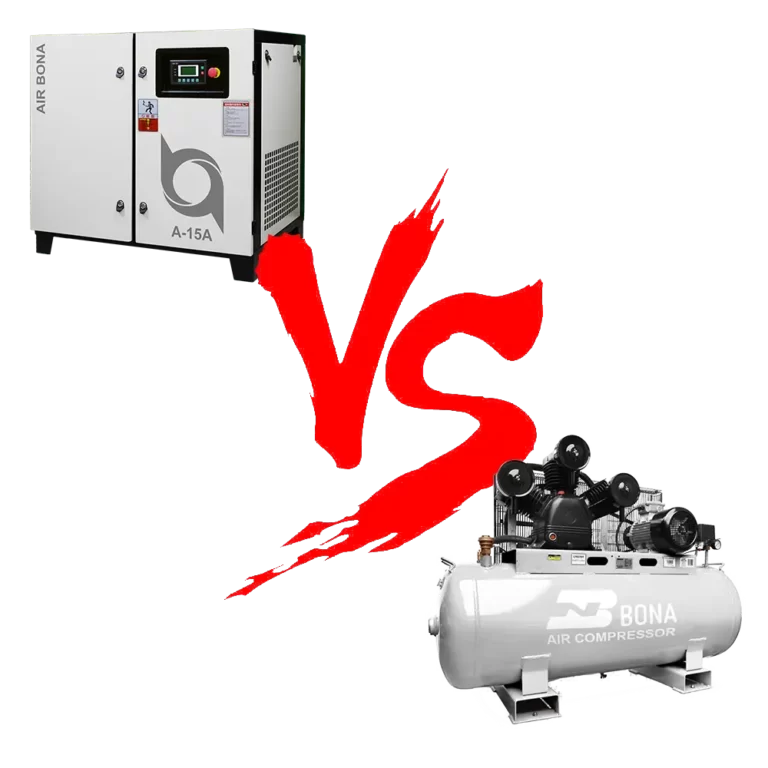

Compressed air is widely used in industry, and the cost of compressed air is a concern for every customer. The initial equipment investment is only a part of the cost, and operating expenses are the main cost of compressed air. Let’s look at it together! 1. Appropriate air compressor selection Model selection is the first…